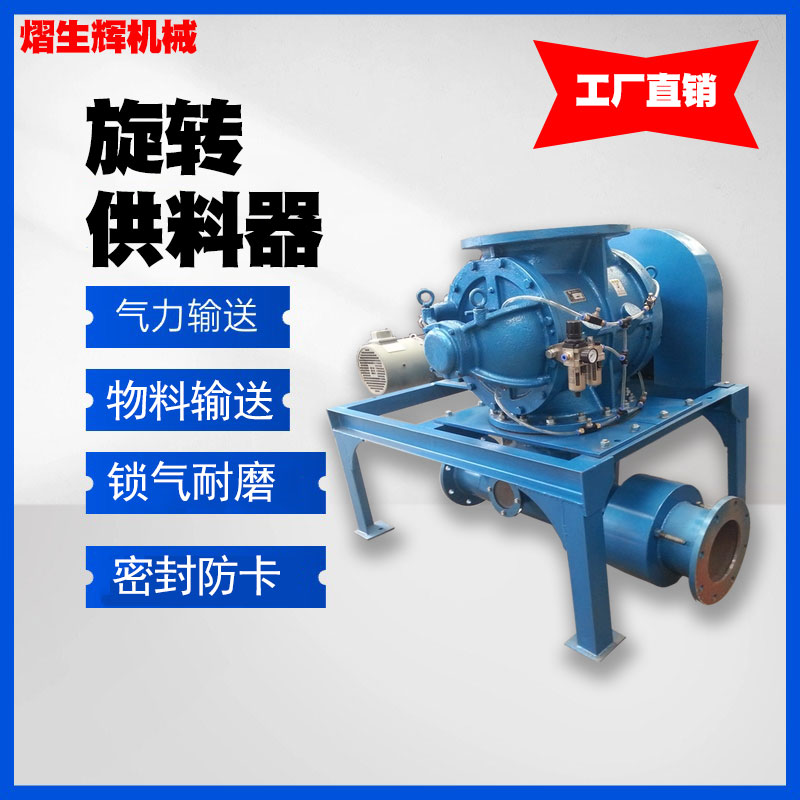

在粉体输送、颗粒加工等工业场景中,旋转供料器如同一位不知疲倦的 “物料指挥官”,通过精密配件的协同运作,将各类物料均匀、稳定地输送至指定位置。这些看似不起眼的配件,实则是构成设备核心功能的 “交响乐团”,每个部件都在各自的 “声部” 发挥着关键作用,共同奏响高效供料的 “工业乐章”。

In industrial scenarios such as powder conveying and particle processing, the rotary feeder acts as a tireless "material commander", delivering various materials evenly and stably to designated locations through the coordinated operation of precision components. These seemingly inconspicuous accessories are actually the "symphony orchestra" that constitutes the core function of the equipment. Each component plays a key role in its own "voice" and together plays the "industrial symphony" of efficient feeding.

旋转供料器的核心执行部件是叶轮,它如同设备的 “心脏瓣膜”,决定着物料输送的效率与稳定性。叶轮通常由轮毂和叶片组成,根据输送物料的特性(如粒度、硬度、腐蚀性),叶片材质可选用铸铁、铝合金、不锈钢甚至耐磨塑料。例如,输送石英砂、煤粉等磨损性强的物料时,叶片表面会喷涂碳化钨涂层或采用高锰钢材质,将耐磨寿命提升 3-5 倍;输送食品级物料(如面粉、糖粉)时,叶轮会选用食品级不锈钢(如 304L),并进行镜面抛光处理,避免物料残留与污染。叶片形状也大有讲究,直叶片适用于流动性好的颗粒料,弧形叶片可减少物料在旋转过程中的冲击,而带倾角的叶片则能适应黏性物料的输送,防止堵塞。

The core executing component of the rotary feeder is the impeller, which is like the "heart valve" of the equipment, determining the efficiency and stability of material transportation. The impeller is usually composed of a hub and blades. Depending on the characteristics of the conveyed material (such as particle size, hardness, corrosiveness), the blade material can be selected from cast iron, aluminum alloy, stainless steel, or even wear-resistant plastic. For example, when transporting materials with strong wear resistance such as quartz sand and coal powder, the blade surface will be sprayed with tungsten carbide coating or made of high manganese steel material, which can increase the wear resistance life by 3-5 times; When transporting food grade materials such as flour and sugar powder, the impeller will be made of food grade stainless steel (such as 304L) and polished with a mirror finish to avoid material residue and contamination. The shape of the blades also has its own requirements. Straight blades are suitable for granular materials with good flowability, curved blades can reduce the impact of materials during rotation, and angled blades can adapt to the transportation of viscous materials and prevent blockage.

包裹叶轮的壳体是设备的 “骨骼框架”,分为上壳体(进料端)和下壳体(出料端)。壳体材质多为铸铁或钢板焊接结构,对于腐蚀性物料(如化肥、化工粉末),会采用不锈钢(如 316L)或内衬聚四氟乙烯,从源头抵御介质侵蚀。壳体内部通常设计有导流槽或耐磨衬板,导流槽引导物料均匀进入叶轮腔,减少冲击噪声;耐磨衬板(如氧化铝陶瓷衬板、高分子聚乙烯板)覆盖在物料冲刷严重的区域(如进料口下方),当衬板磨损达原厚度的 1/3 时,可单独拆卸更换,避免整体壳体报废。壳体与叶轮之间的间隙至关重要,一般控制在 0.1-0.3 毫米,间隙过大易导致物料泄漏,过小则可能因热胀冷缩引发卡滞,需通过精密加工(如数控铣削)保证尺寸精度。

The shell that wraps around the impeller is the "skeleton frame" of the equipment, which is divided into an upper shell (feed end) and a lower shell (discharge end). The shell material is mostly cast iron or steel plate welded structure. For corrosive materials such as fertilizers and chemical powders, stainless steel (such as 316L) or lined with polytetrafluoroethylene will be used to resist medium erosion from the source. The interior of the shell is usually designed with a guide groove or wear-resistant lining plate, which guides the material evenly into the impeller cavity and reduces impact noise; Wear resistant lining plates (such as alumina ceramic lining plates, polymer polyethylene plates) cover areas with severe material erosion (such as below the feed inlet). When the lining plate wears down to one-third of its original thickness, it can be disassembled and replaced separately to avoid the overall shell being scrapped. The gap between the shell and the impeller is crucial, generally controlled at 0.1-0.3 millimeters. A gap that is too large can lead to material leakage, while a gap that is too small may cause jamming due to thermal expansion and contraction. Precision machining (such as CNC milling) is required to ensure dimensional accuracy.

密封装置是旋转供料器的 “防护盾”,防止物料泄漏或外界粉尘进入。轴向密封(叶轮与壳体端面之间)常用迷宫式密封、填料密封或机械密封:迷宫式密封通过多层环形间隙形成气障,结构简单但密封效果一般,适用于常压或低粉尘环境;填料密封(如石墨盘根、聚四氟乙烯填料)通过压盖压紧填料实现密封,需定期调整压盖松紧度,避免填料磨损导致漏粉;机械密封则利用动静环的精密配合(端面平整度≤0.0009 毫米),在高压或高真空场景中表现优异,如气力输送系统中的正压供料(压力≤0.6MPa)。径向密封(叶片与壳体内壁之间)多采用弹性密封片(如不锈钢弹簧片、聚氨酯胶条),密封片一端固定在叶片边缘,另一端紧贴壳体内壁,随叶片旋转形成动态密封,当密封片磨损后可单独更换,更换过程仅需拆卸壳体端盖,耗时约 30 分钟。

The sealing device is the "protective shield" of the rotating feeder, preventing material leakage or external dust from entering. Axial seal (between impeller and shell end face) commonly used labyrinth seal, packing seal or mechanical seal: labyrinth seal forms an air barrier through multiple layers of annular gaps, with a simple structure but general sealing effect, suitable for atmospheric pressure or low dust environment; Packing sealing (such as graphite packing and polytetrafluoroethylene packing) is achieved by compressing the packing with a gland, and the tightness of the gland needs to be adjusted regularly to avoid powder leakage caused by packing wear; Mechanical seals utilize the precise fit of the dynamic and static rings (end face flatness ≤ 0.0009 millimeters) to perform excellently in high-pressure or high vacuum scenarios, such as positive pressure feeding in pneumatic conveying systems (pressure ≤ 0.6 MPa). Radial sealing (between the blade and the inner wall of the shell) often uses elastic sealing plates (such as stainless steel spring plates, polyurethane rubber strips). One end of the sealing plate is fixed to the edge of the blade, and the other end is tightly attached to the inner wall of the shell, forming a dynamic seal as the blade rotates. When the sealing plate wears out, it can be replaced separately. The replacement process only requires dismantling the end cover of the shell, which takes about 30 minutes.

驱动系统是旋转供料器的 “动力源”,包括电机、减速机和联轴器。电机类型根据工况选择,普通工况采用三相异步电机,防爆环境选用隔爆型电机(如 Ex d IIB T4),变频调速电机则用于需要调节供料量的场景(调速范围通常为 10-100rpm)。减速机承担降速增矩的任务,齿轮减速机(传动效率≥90%)适用于大扭矩需求,蜗轮蜗杆减速机(结构紧凑)适合空间受限场景,两者均需定期更换润滑油(更换周期:齿轮油 6000 小时,蜗轮油 4000 小时)。联轴器连接电机与主轴,弹性联轴器(如梅花形联轴器)可吸收振动和轴向偏移,补偿两轴的安装误差(允许径向偏差≤0.2 毫米,角度偏差≤1.5°),刚性联轴器则用于高精度传动,需确保电机与主轴的同轴度误差≤0.05 毫米。

The drive system is the "power source" of the rotary feeder, including the motor, reducer, and coupling. The type of motor is selected according to the working conditions. For ordinary working conditions, three-phase asynchronous motors are used. For explosion-proof environments, explosion-proof motors (such as Ex d IIB T4) are selected. Variable frequency speed regulating motors are used in scenarios where the feeding amount needs to be adjusted (the speed regulation range is usually 10-100rpm). The reducer is responsible for reducing speed and increasing torque, the gear reducer (transmission efficiency ≥ 90%) is suitable for high torque requirements, and the worm gear reducer (compact structure) is suitable for space limited scenarios. Both require regular replacement of lubricating oil (replacement cycle: gear oil 6000 hours, worm gear oil 4000 hours). Couplings connect the motor and the spindle. Elastic couplings (such as plum blossom couplings) can absorb vibration and axial displacement, compensate for installation errors of the two shafts (allowing radial deviation ≤ 0.2 millimeters and angular deviation ≤ 1.5 °), while rigid couplings are used for high-precision transmission, ensuring that the coaxiality error between the motor and the spindle is ≤ 0.05 millimeters.

本文由旋转供料器友情奉献.更多有关的知识请点击:http://www.sdyshjx.com/我们将会对您提出的疑问进行详细的解答,欢迎您登录网站留言.

This article is dedicated to friendship For more information, please click: We will provide detailed answers to your questions. You are welcome to log in to our website and leave a message

联系电话

二维码