仓泵是气力输送系统中不可或缺的组成部分,它具有输送距离远、输送能力大、管道布置灵活、减少设备投资等特点。由于其应用场景多集中在工业领域,很多行业外的人对它并不熟悉,甚至闻所未闻,对其工作原理更是知之甚少。下面就来详细了解一下仓泵的相关知识。

Warehouse pump is an indispensable component of pneumatic conveying system, which has the characteristics of long conveying distance, large conveying capacity, flexible pipeline layout, and reduced equipment investment. Due to its application scenarios mostly concentrated in the industrial field, many people outside the industry are not familiar with it, or even unheard of, and know very little about its working principle. Let's take a detailed look at the relevant knowledge of warehouse pumps below.

仓泵的卸料方式主要有两种,其中底部出料是最为常见的一种。在这种方式中,罐内的物料通过圆锥面充气槽的充气、喷嘴喷气或其他专门设计的方法实现流态化,使物料能够顺利从底部排出。另一种卸料方式是上部出料,通过在罐底部设置流态化充气板,让物料在气体的作用下向上流动,从而从罐的上部卸出。不同的卸料方式适用于不同的物料特性和输送需求,比如对于流动性较差的物料,可能需要更强劲的充气装置来辅助卸料,而输送气体在罐内不同输入水平上的分布情况,会根据输送物料的颗粒大小、比重、湿度等性质进行针对性设计,以确保卸料过程稳定高效。

There are two main unloading methods for warehouse pumps, among which bottom discharge is the most common. In this method, the material inside the tank is fluidized through the inflation of the conical surface inflation groove, nozzle spraying, or other specially designed methods, allowing the material to be smoothly discharged from the bottom. Another unloading method is upper discharge, which involves setting up a fluidized inflatable plate at the bottom of the tank to allow the material to flow upward under the action of gas and be discharged from the upper part of the tank. Different unloading methods are suitable for different material characteristics and conveying needs. For example, for materials with poor fluidity, stronger inflation devices may be required to assist in unloading. The distribution of conveying gas at different input levels in the tank will be designed according to the particle size, specific gravity, humidity, and other properties of the conveyed material to ensure a stable and efficient unloading process.

从工作原理来看,仓泵的运行紧密依托气力输送系统的整体协作。当系统启动后,物料首先从料仓落入仓泵内部,此时仓泵会先完成进料阶段,待物料达到预设的装载量后,进料口关闭,进入加压阶段。随后,来自气源装置的高压气体被通入仓泵罐内,使罐内形成一定的压力,在压力的作用下,物料被充分流态化,呈现出类似流体的状态。当罐内压力达到设定值时,出料阀打开,流态化的物料便在高压气体的推动下,沿着输送管道被输送至末端的收料仓。在整个输送过程中,仓泵就像一个 “加压输送站”,通过周期性地完成进料、加压、输送、排气等环节,实现物料的连续或间断输送。

From the perspective of working principle, the operation of the bin pump relies closely on the overall cooperation of the pneumatic conveying system. After the system is started, the material first falls from the silo into the interior of the silo pump. At this time, the silo pump will complete the feeding stage first. When the material reaches the preset loading capacity, the feeding port will be closed and enter the pressurization stage. Subsequently, high-pressure gas from the gas source device is introduced into the bin pump tank, creating a certain pressure inside the tank. Under the action of pressure, the material is fully fluidized, presenting a fluid like state. When the pressure inside the tank reaches the set value, the discharge valve opens, and the fluidized material is transported along the conveying pipeline to the receiving bin at the end under the push of high-pressure gas. Throughout the entire conveying process, the bin pump acts as a "pressurized conveying station", periodically completing processes such as feeding, pressurization, conveying, and exhaust to achieve continuous or intermittent conveying of materials.

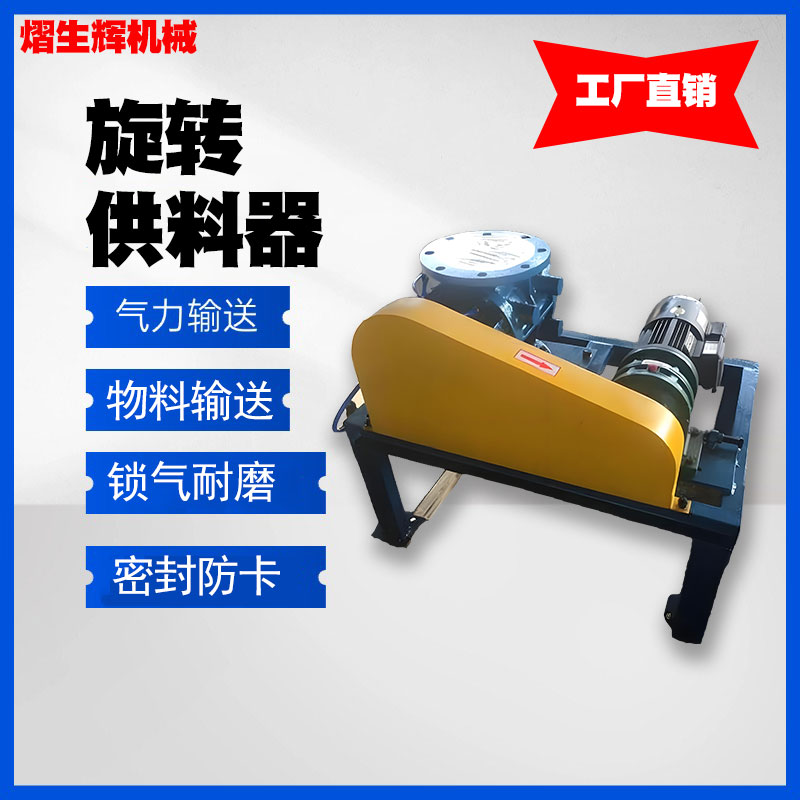

气力输送系统一般采用空气压缩机作为气源,除了仓泵,还会配备高压旋转阀、螺旋泵等作为供料装置,它们共同构成了完整的物料输送体系。物料由料仓落入供料装置后,系统向输送管道内输入高压气体,让气体和物料充分混合,使物料流态化,之后通过高压气流将物料输送到末端收料仓,而气体则经分离装置过滤后排出大气,避免对环境造成影响。

Pneumatic conveying systems generally use air compressors as the gas source. In addition to bin pumps, high-pressure rotary valves, screw pumps, and other feeding devices are also equipped, which together form a complete material conveying system. After the material falls from the silo into the feeding device, the system inputs high-pressure gas into the conveying pipeline to fully mix the gas and material, making the material fluidized. Then, the material is transported to the end receiving silo through high-pressure airflow, and the gas is filtered by the separation device and discharged into the atmosphere to avoid affecting the environment.

仓泵的控制系统具有自动化程度高的特点,操作起来十分简便,能够自动完成计量、计数、显示及报警等功能,大大减少了人工操作的工作量和误差。同时,其控制系统用气、泵顶料仓气化等所需的气体,不需要另外配备气源,可直接从系统的气源装置获取,节省了额外的设备投入。此外,仓泵的密封性良好,运行过程可靠,易损部件较少,这不仅降低了日常维护的难度,也延长了设备的使用寿命,能够在长期运行中保持稳定的输送效率,满足工业生产中对物料输送的持续需求。

The control system of the warehouse pump has a high degree of automation, which is very easy to operate. It can automatically complete functions such as metering, counting, display, and alarm, greatly reducing the workload and errors of manual operation. At the same time, the gas required for the control system, pump top silo gasification, etc., does not require an additional gas source and can be directly obtained from the system's gas source device, saving additional equipment investment. In addition, the sealing performance of the warehouse pump is good, the operation process is reliable, and there are fewer vulnerable parts. This not only reduces the difficulty of daily maintenance, but also extends the service life of the equipment, which can maintain stable conveying efficiency in long-term operation and meet the continuous demand for material conveying in industrial production.

本文由仓泵友情奉献.更多有关的知识请点击:http://www.sdyshjx.com/我们将会对您提出的疑问进行详细的解答,欢迎您登录网站留言.

This article is dedicated to friendship For more information, please click: We will provide detailed answers to your questions. You are welcome to log in to our website and leave a message

联系电话

二维码